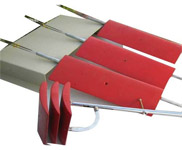

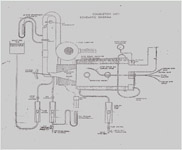

PL- Propulsion Lab Equipments

We are one of the prominent manufacturers and suppliers of the superior quality range of Propulsion lab, which include Free Wall Jet Experiments. The entire range is fabricated using high grade raw materials in compliance with the set industry norms using advanced technology. Our customers can avail this entire range at genuine prices.